Pioneering a Circular Economy

Central to our journey toward waste-free workplaces is the drive toward a circular economy.

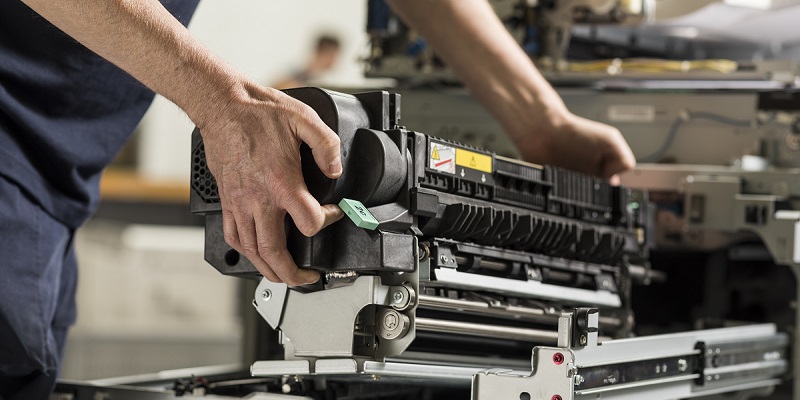

At Xerox, we believe that reducing waste is not only good for the environment, but also for your business. That’s why we pioneered this practice decades ago, by remanufacturing, refurbishing and recycling office equipment. Our devices are built to last, with fewer parts, easy disassembly, and strict chemical standards. We want you to enjoy high-quality performance while helping you reduce your environmental impact.

A longstanding commitment to waste-reduction

We have embedded circularity in our products since 1959, long before the term circular economy was created, and take a life cycle approach to low carbon design, addressing impacts from raw materials and manufacturing, transportation, use and maintenance, through extended life management.

With the rise of regulations on resource use and stakeholder sensitivity to waste management and environmental impacts, more consumers and organizations now prioritize circularity in their purchasing decisions and brand perception.

Supporting our clients' circularity needs

Our vision for circularity extends to our clients’ workplaces, where electronics and supplies at the end of their useful life can come full circle to become the raw materials of tomorrow. Where, without compromise to product quality and the client experience, natural resources are conserved, and waste becomes obsolete.

To achieve this vision, we incorporate a comprehensive Design for Sustainability approach, covering four key phases of a circular economy:

Design

Design

Design

The design process centers on the careful selection of raw materials, with an emphasis on safety, more responsible use of recoverable and recyclable materials, adherence to ecolabel criteria and product life cycle impacts.

Safety

Design goals are established for each Xerox® product at the start of the development cycle, focusing on selecting parts and materials that are safe for use and the environment. Xerox toxicologists conduct comprehensive assessments of new materials to ensure compliance with global regulations, hazard classifications, and waste handling requirements. Since 2006, products have been designed to meet the European Restriction of Hazardous Substances (RoHS) requirements. Xerox maintains compliance with all global chemical regulations through proactive regulatory tracking.

Recycled Materials

Xerox incorporates recycled materials in new and refurbished equipment and remanufactured supplies. Since 2021, the company has increased the amount of post-consumer recycled (PCR) plastic content in printers, multifunction devices, and toner cartridges. New products feature as much as 47% PCR plastic content, with an average of 9% across the equipment portfolio. The goal is for all new products to have at least 25% PCR at launch. Additionally, Xerox aims to eliminate single-use plastics and increase recycled content in packaging to 30% or greater by 2028.

Ecolabel Certification

Design goals include sustainability elements framed around the Electronic Products Environmental Assessment Tool (EPEAT ®) ecolabel criteria. Product criteria reflect several categories of environmental attributes that span the life cycle of electronic products: design for repair, upgrade, reuse, recycling, product longevity, energy conservation, end-of-life management and sustainable packaging. Xerox products are also designed to meet ENERGY STAR ® and Blue Angel ecolabel requirements, which have stringent design standards. 93% of the current portfolio is certified to one or more of these ecolabels.

Life cycle Impacts

Xerox integrates life cycle thinking into product and service development. Life Cycle Assessments (LCAs) quantify the environmental impacts of a product across its life stages. The goal is for 100% of new products to have an LCA at launch. Currently, 80% of the portfolio has LCAs, informing users of product carbon footprints and identifying opportunities to reduce environmental impacts.

Manufacturing

Manufacturing

Manufacturing

Xerox's manufacturing process emphasizes the repurposing of recovered materials in equipment and supplies and implementing robust environmental management systems. Parts and components that still have useful life are recovered and given a second life. Product families are designed with high commonality, allowing up to 95% of machine components by weight to be repurposed in the production of circular economy offerings.

No Compromise

The goal for circular products, hardware and supplies, is to meet the same performance, reliability, and quality standards as newly built products. This principle extends to spare parts that are returned and reconditioned, aiming to extend the life of equipment, parts, and supplies by reprocessing them. Xerox has embraced this approach since 1959. Reprocessing facilities adhere to the same standards as original factories, including ISO 9001 (quality) and 14001 (environmental), and employ more responsible recycling practices for parts that cannot be used.

Reducing Emissions

Xerox circular economy offerings demonstrate significant CO2e savings, estimated at more than 90% during the raw material and manufacturing stages of the life cycle. This reduction is due to the use of fewer new materials and parts, translating to up to 1.3 tons of CO2e emissions savings compared to newly built devices. These estimations are based on internal lifecycle assessments.

Toner Manufacturing

In 2023, over 1.7 million Xerox® Toner Cartridges were manufactured using recovered cartridges. Xerox has set a goal for remanufactured toner cartridges to have a minimum of 75% post-consumer materials (PCM) reuse, currently exceeding this goal with an average of 90% reuse by weight.

Consumption

Consumption

Consumption

The consumption process includes best practices that deliver energy savings while printing, efficiencies through innovation and reduced environmental impacts via Xerox® Remote Print Services.

Energy Savings

Xerox has significantly reduced the power consumption of its printers and multifunction devices through various innovations. These include adjustments in fuser design, changes in toner properties, development of more efficient electronic controls, and improvements in the xerographic system. Currently, Xerox's average energy consumption is approximately 30% below ENERGY STAR limits. Energy conservation features in Xerox® printers and multifunction printers include duplex printing, N-up printing, energy savings modes, high-yield cartridges, and smart print drivers. The Earth Smart print driver feature allows users to choose more sustainable printing options with a single click, such as 2-sided printing, eliminating banner pages, and printing multiple pages per sheet.

Toner Innovation

Xerox® EA Toner (emulsion aggregation) is designed to reduce the environmental impact of printing. These toners are energy-efficient both in their manufacturing and during use, requiring less energy per page compared to conventional toner. More prints can be made per pound or kilogram of EA toner, and the toner is de-inkable, allowing the paper to be recycled. Xerox's xerographic products have achieved an INGEDE de-inking score of 100/100.

Remote and Self Service

Xerox employs various technologies to minimize the need for onsite service and maximize client uptime. Tools such as Xerox® Remote Print Services, Xerox Services Manager, the Xerox® Quick Resolve App, and automate common tasks, delivering efficiency and quicker problem resolution. These technologies also reduce environmental impact by decreasing the number of site visits required.

Extended Life

Extended Life

End of Life

Xerox's global collection programs enable end-of-life management, giving returns a second, useful life. The goal is to achieve 100% landfill avoidance of returned equipment, parts, and supplies, with a demonstrated track record of achieving 98% or more.

Equipment

Xerox is committed to collecting and repurposing equipment at the end of its useful life. The process includes:

Reuse of complete end item/used equipment: Equipment returns are evaluated for potential refurbishment and may undergo reconditioning and verification to return to a high standard before redeployment.

Manufacture or conversion into a newer-generation product or part: Equipment is disassembled, cleaned, reassembled, inspected, and tested to original performance standards.

Reuse of major modules, subcomponents, and parts for spares or manufacturing: Usable parts are stripped from machines that have outlived their useful life and repurposed in upstream and downstream processes.

Material recycling: Remaining machine parts are stripped of recyclable materials and those requiring special disposal services, with the remainder sent to an industrial reclaim facility.

Supplies

The is central to extending the life of supplies. This collection and reuse/recycling program efficiently manages supplies at end-of-life and recovers materials for use in remanufactured supply items, reducing raw material demand and diverting consumables from landfill. Clients can return spent units via single returns, Eco boxes, or pallets. Returned items are collected, assessed, disassembled, cleaned, inspected, and packaged for shipment. Toner collected from spent cartridges is reused or reprocessed. Items unsuitable for remanufacturing are recycled or recovered through energy from waste. Recycled waste toner and reclaimed toner may account for 25% of new toner’s weight, reducing raw material costs. More than 35 countries participate in the .

See our latest performance figures in our corporate social responsibility report, goals, and progress summary

*Blue Angel and products in the scope of the EU Ecodesign Framework standards have access to select spare parts for seven years

Preventing and Managing Waste

We are committed to producing waste-free products in waste-free facilities to help our clients reduce waste. Our aim is to design products, packaging and supplies that make efficient use of resources, minimize waste, reuse material where feasible (including recycled plastics), and recycle what can't be reused.

At Xerox, we not only remanufacture, reuse and recycle equipment, but we expect the same commitment to sustainability from our suppliers. This way, we can reduce our environmental impact together. Packaging waste is also being reduced by removing single use plastics and increasing recycled content.

We also make it easy to repair and maintain your Xerox products. If you buy a new Xerox product, you can rest assured that you will have access to spare parts.* This means you can keep your Xerox products running smoothly and efficiently for longer, while reducing waste and saving money.

Globally, our returns programs for equipment resale and remanufacture in conjunction with parts recycling prevented 27,999 metric tons of waste from entering landfills in 2022. 4.3 million consumables were also returned in 2022 from the 35 countries participating in the Xerox Supplies Recycling Program, enabling 1.6 million Xerox toners to be manufactured using recovered cartridges.

As much as 47% post-consumer recycled plastic is included in our latest desktop office printers, and we use as much as 95% of reclaimed parts in larger devices.

Links to Recycling and Extended Life Resources

Explore services and operations that are helping to reduce environmental impacts

Xerox Supplies Recycling Program

Millions of cartridges and toner containers are returned for reuse or recycling each year through the Xerox Supplies Recycling Program.

Xerox Reverse Logistics

Since 2009, Xerox has diverted over 600 thousand metric tons of returned equipment, parts, and supplies from landfill by remanufacturing, reusing, or recycling.

Waste-free Factories

Since the 1990s, our Waste-Free Factory initiative has employed an ISO 14001-compliant environmental management system to help achieve a 93% recycling rate for non-hazardous materials.

Frequently Asked Questions

What are the environmental, economic and societal benefits of a circular economy?

What are the environmental, economic and societal benefits of a circular economy?

A circular economy is a way of using resources more efficiently and reducing waste. It has positive impacts on the environment, the economy, and society. For example, it helps conserve natural resources, lower energy use and greenhouse gas emissions, save costs for manufacturers and customers, create jobs and opportunities, and improve health and well-being. A circular economy also supports the United Nations Sustainable Development Goals (SDGs) that aim to end poverty, protect the planet, and ensure peace and prosperity for all.

How has Xerox embraced a circular economy?

How has Xerox embraced a circular economy?

Xerox follows a Design for Sustainability approach that covers the four stages of a circular economy: design, manufacturing, consumption, and extended life management. We design our products with the environment in mind, with careful selection of raw materials, recovered and recycled content, and safety, and meeting high standards of ecolabels such as ENERGY STAR, EPEAT, and Blue Angel. We re-purpose and remanufacture our equipment and supplies and manage our operations with environmental best practices. We help our customers use our products more efficiently and responsibly, with features such as energy saving, more responsible printing, and remote service. Plus, we offer a global collection and recycling program for products at the end of their life, giving them a second life and reducing the need for new materials.

What does Xerox consider when designing products?

What does Xerox consider when designing products?

We consider the full life cycle of our products, from raw materials to the manufacturing, delivery, use, maintenance and end-of-life management. We set and monitor product goals in each of these phases during the development process. We apply Design for Sustainability criteria to our equipment, supplies, and packaging, to meet or exceed the market and regulatory requirements, and minimize the environmental footprint. We aim to have 100% of our eligible new products meet stringent ecolabels, such as ENERGY STAR, EPEAT, and Blue Angel, where and when applicable, and to assess the life cycle impacts of each product.

Do Xerox products include recycled and reused materials?

Do Xerox products include recycled and reused materials?

We use post-consumer recycled (PCR) plastic content in our devices and toner cartridges where possible, with up to 47% PCR plastic in newer products. We also use recovered parts from returned devices in our products. Up to 95% by weight of returned devices can be used in refurbished equipment. Returned toner cartridges are remanufactured, using on average 90% recovered components. All the re-purposed parts meet product performance and factory specifications.

What are the benefits of circular products?

What are the benefits of circular products?

Internal studies have estimated circular products save an estimated CO2e savings of at least 90% during the raw material and manufacturing stages of the device lifecycle. As much as 1.3 tons of CO2 emissions vs. a new build device, the equivalent life cycle of 146 gallons of gasoline saved or C02 captured by 21 tree seedlings growing for 10 years, is realized over a five-year product lifecycle. (4)

How does Xerox conserve resources in manufacturing operations?

How does Xerox conserve resources in manufacturing operations?

Xerox manufacturing facilities are certified to ISO 14001 environmental management standard and are committed to lower water and energy use by 20% and 25% respectively by 2030 and 2025 (from 2020 and 2016 baselines). Some sites also use renewable energy sources. More than 10 sites and over 35 partners globally perform reprocessing and repair activities, which extend the life of materials and parts and minimize the need for new resources.

How do Xerox products help to lower environmental impacts of printing?

How do Xerox products help to lower environmental impacts of printing?

Xerox products have features that optimize energy consumption, such as print driver settings for 2-sided printing, multiple-images per page, and draft modes, and low power and sleep modes when idle. You can also print more responsibly by using best practices, such as pull printing. Xerox provides analytics and dashboards to show the environmental impact of your printing, and options to plant trees or buy carbon.

Can Xerox devices be repaired remotely?

Can Xerox devices be repaired remotely?

Xerox devices can be repaired remotely, with the help of CareAR, a live visual assistance and guidance innovation that allows remote troubleshooting and resolution of issues. Other advanced customer service repair programs are available for certain products. Proactive maintenance and remote service reduce the need for on-site service visits, which avoids carbon emissions. In one year, CareAR avoided 57,000 site visits and 594,800 Kg of carbon emissions.

Does Xerox have global returns programs for equipment and supplies?

Does Xerox have global returns programs for equipment and supplies?

Xerox has takeback and return programs for end-of-life equipment and spent supplies in multiple geographies. Learn more about equipment recycling options or donating Xerox devices.

Learn about our supplies collection and reuse/recycling program, to see how you can .

What methodology does Xerox employ for returns?

What methodology does Xerox employ for returns?

Xerox strives to repurpose as much as possible from returned equipment and supply items. A returned item may be refurbished entirely or reprocessed with some parts or components replaced. If the item is beyond repair, usable parts and components are salvaged for spare parts. The remaining portions are recycled responsibly. Only as a last resort, materials that cannot be recycled are processed as waste energy.

What can I do to support a circular economy?

What can I do to support a circular economy?

You can support the circular economy by choosing products with ecolabels, opting for refurbished or circular products, utilizing devices efficiently, maintaining them properly, and returning used consumables and equipment at end of their first life.

For additional information about environmental sustainability at Xerox, see our corporate social responsibility report, goals, and progress summary.

Sources:

2. Deloitte The Sustainable Consumer 2023

4. United States Environmental Protection Agency Greenhouse Gas Equivalencies Calculator | US EPA

Environment, Health, Safety, and Sustainability at Xerox

Sustainability in business has never been more important. Explore Xerox solutions for more sustainable printing, reduced environmental waste and more EHS efforts.