Zuzu Print finds productivity gains and 40% profit increase with the Xerox® Iridesse® Production Press.

Lithuania-based Zuzu Print takes pride in its ability to reinvent itself for a changing market—a level of adaptability that has resulted in a decade of steady growth. But with a growing demand for Beyond CMYK embellishments from some of its largest and most valued customers, profits potential was literally flying out the door and into the hands of outsourced partners.

Looking for a solution that would allow for increased productivity, production capability, and—critically—the ability to add digital Beyond CMYK embellishments—Zuzu Print turned to Xerox.

“Xerox has proved to be a reliable partner, with innovative technologies that contribute to our business growth. I expect that Xerox will continue developing and bringing new innovations to the market.”

—Tomas Birbalas, Owner, Zuzu Print

Zuzu Print found the ultimate solution—the Xerox® Iridesse® Production Press with its ability to print 120 pages per minute on a wide range of media (including the heavy stocks commonly used for packaging), as well as its Beyond CMYK capabilities.

Bringing home the gold: Case Study Highlights

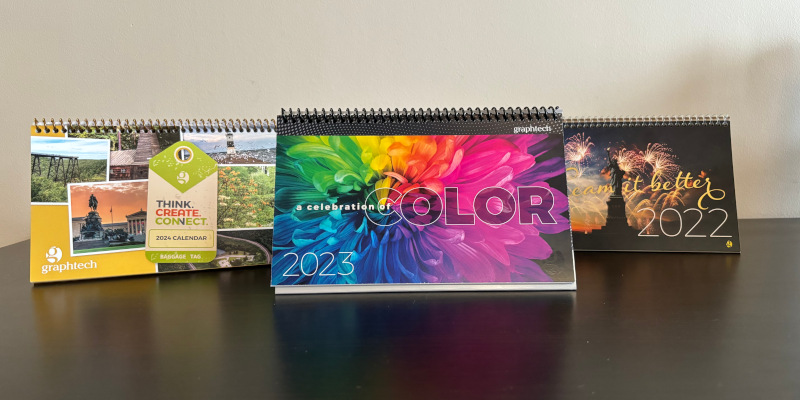

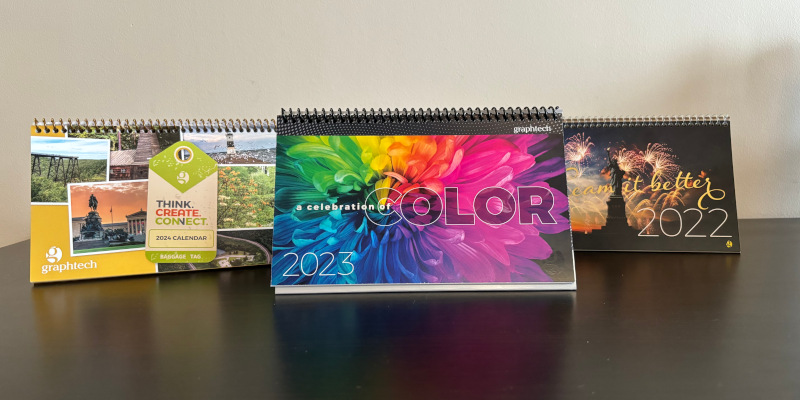

Beyond CMYK technology allowed Zuzu Print to keep 100% of their embellishment work in house—resulting in an astonishing 40% gain in profit.

They were up and running with Gold, Silver, White, Fluorescent Pink and Clear Specialty Dry Inks in no time, utilizing training and tools provided by The Genesis Initiative, a collection of free resources provided by Xerox to print operators and designers.

Iridesse’s built-in automation—including Xerox® PredictPrint® Media Manager—has eliminated production roadblocks, allowing them to keep up with growing demand and providing powerful, competition busting momentum for the future.

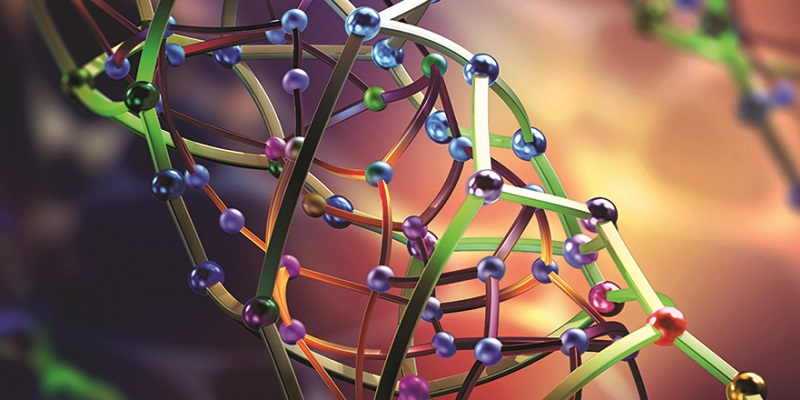

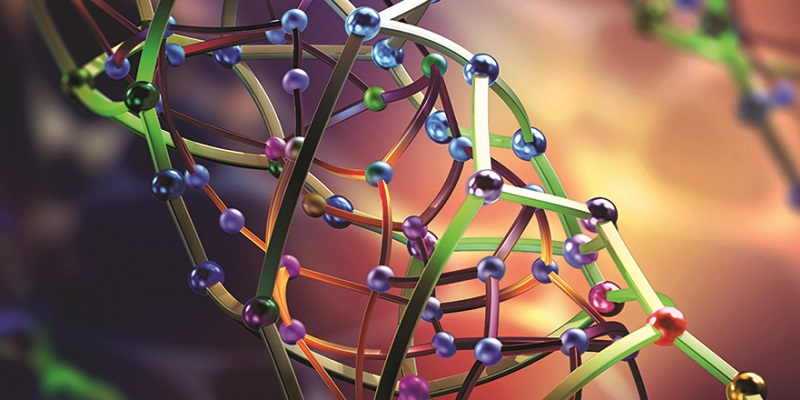

Xerox® Iridesse® Production Press

Powers a more brilliant future by delivering more “wow” impact per printed page through digital specialty enhancements.

Graphic and Print Design Brilliance

Go beyond CMYK with digital printing.

Xerox® PredictPrint Media Manager Software

An effortless way to optimal output on every print run. Scan, load and go—backed by the power of AI.

Xerox® Iridesse® Production Press

Print like a pro in seconds. End-to-end automation nails the basics. Inline speciality embellishment options add profit-driving “wow.”

Up to six inline print stations that print in a single pass, at rated speed, with spot on colour-to-colour registration

Optional White, Clear, Silver, Gold, and gamut extension Fluorescent Pink Specialty Dry Inks for enhancements and brand colour matching, plus Media Expansion Low Gloss Clear

AI-guided Xerox® PredictPrint Media Manager Software baselines the press, expediting time to production

Optimize performance with mixed-stock jobs supported by the Xerox® Mixed Media Acceleration Feature

Additional high capacity feeders and inline finishing solutions, including robust configurations that accelerate XLS sheet productivity end-to-end

Related Articles

Virtual Designer Training: Xerox Adaptive CMYK+ Kit

Use popular digital embellishment techniques in your designs with adaptive CMYK+ kits on the Xerox Versant and Xerox PrimeLink Production Press

Xerox Iridesse Virtual Designer Training

Add popular digital Beyond CMYK embellishments to your projects when using the Xerox Iridesse Press.

40 Years Strong: Pronto Reproductions and Xerox Forge a Resilient Partnership in a Shifting Market

See how the partnership between Pronto Reproductions and Xerox continues to drive agility and growth in a shifting market with the Xerox® Iridesse® Production Press.

Spectrum Print Plus – The Business of Colour, Clients, and Commitment - Xerox

“After months of rigorous evaluation, the clear winner had been right in front of us all along—it was the Iridesse!”

Combatting the Top five Production Operation Cost Drivers

Discover effective strategies to combat the top five production operation cost drivers in digital printing. Learn how to optimize your production processes and reduce costs with expert insights from Xerox.

Xerox® Iridesse® Presses: Empowering Clients with On-Demand Printing

See how Xerox® Iridesse® Presses helped a client meet complex client needs with on-demand printing, exact quantities, and specialty embellishments, all while maintaining high standards.