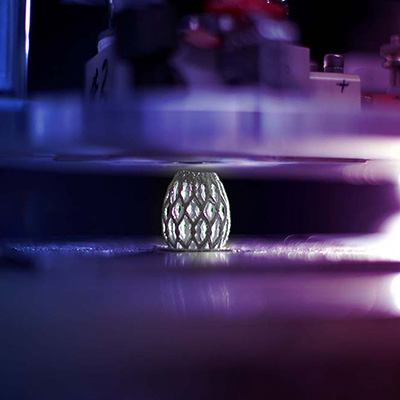

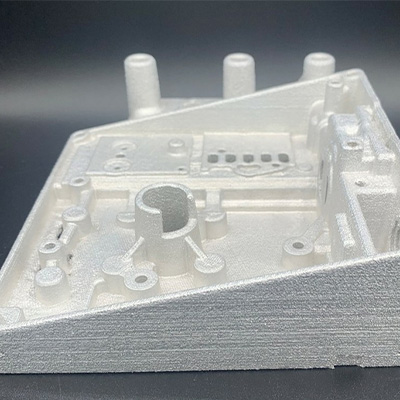

Introducing a New Era of Additive Manufacturing

ADDiTEC acquires Elem Additive

Adaptability and flexibility are necessary tools in today’s ever-changing markets. The operational resiliency achieved through additive manufacturing can empower your business to continue and recover regardless of what’s happening in the world. At Xerox Elem Additive Solutions we are creating solutions that make it easier for our customers to integrate additive manufacturing into their operations and make on-demand manufacturing a reality today. Welcome to the future of additive manufacturing.

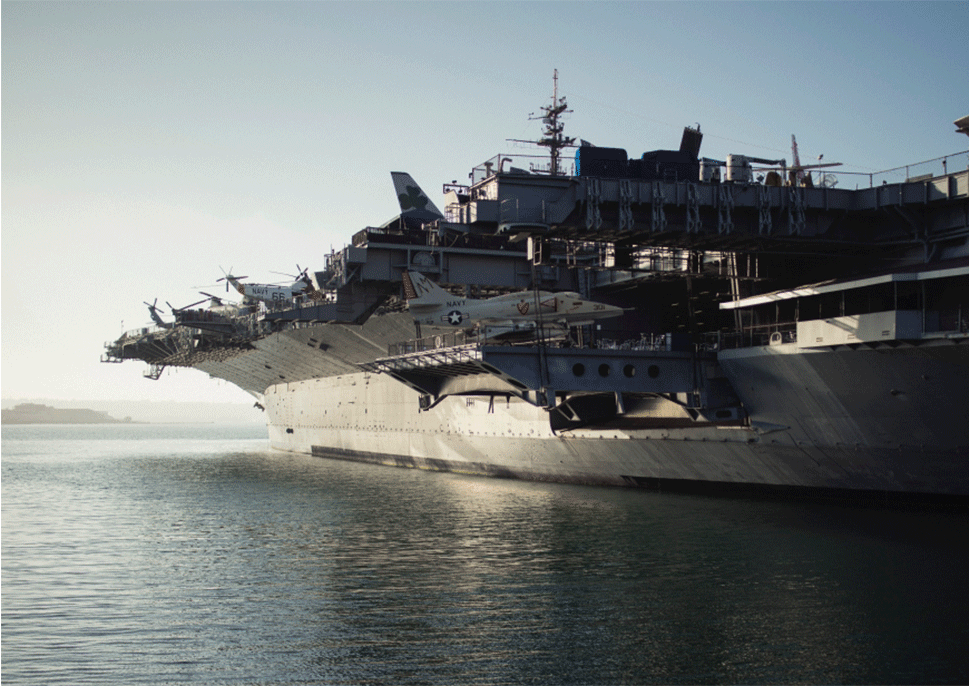

Xerox in the News

Xerox® Elem™ Additive and U.S Navy Deploy First Metal 3D Printer at Sea

Xerox® ElemX™3D metal printer installed on USS Essex (LHD 2) and at-sea trials have begun in Pacific Rim.